Jotun scores Gold in sustainability rating

According to the leading rating of companies’ sustainability performance, Jotun climbs to the top 5%. The Gold score is a result of dedicated work across functions.

Jotun protects the environment and creates value by contributing to the customer’s sustainability ambitions and goals and reducing impacts from our operations.

We see paints and coatings as a vital element of a sustainable future. Every asset needs protection, and this is what we do best: Protecting property against degradation and corrosion. This improves asset longevity, reduces demand for resources and preserves the environment.

Jotun GreenSteps, established in 2010, is our framework to improve the environmental footprint. The goal is to develop sustainable products and solutions, reduce the footprint of our own operations, and support our customers to meet new regulations and achieve their sustainability goals.

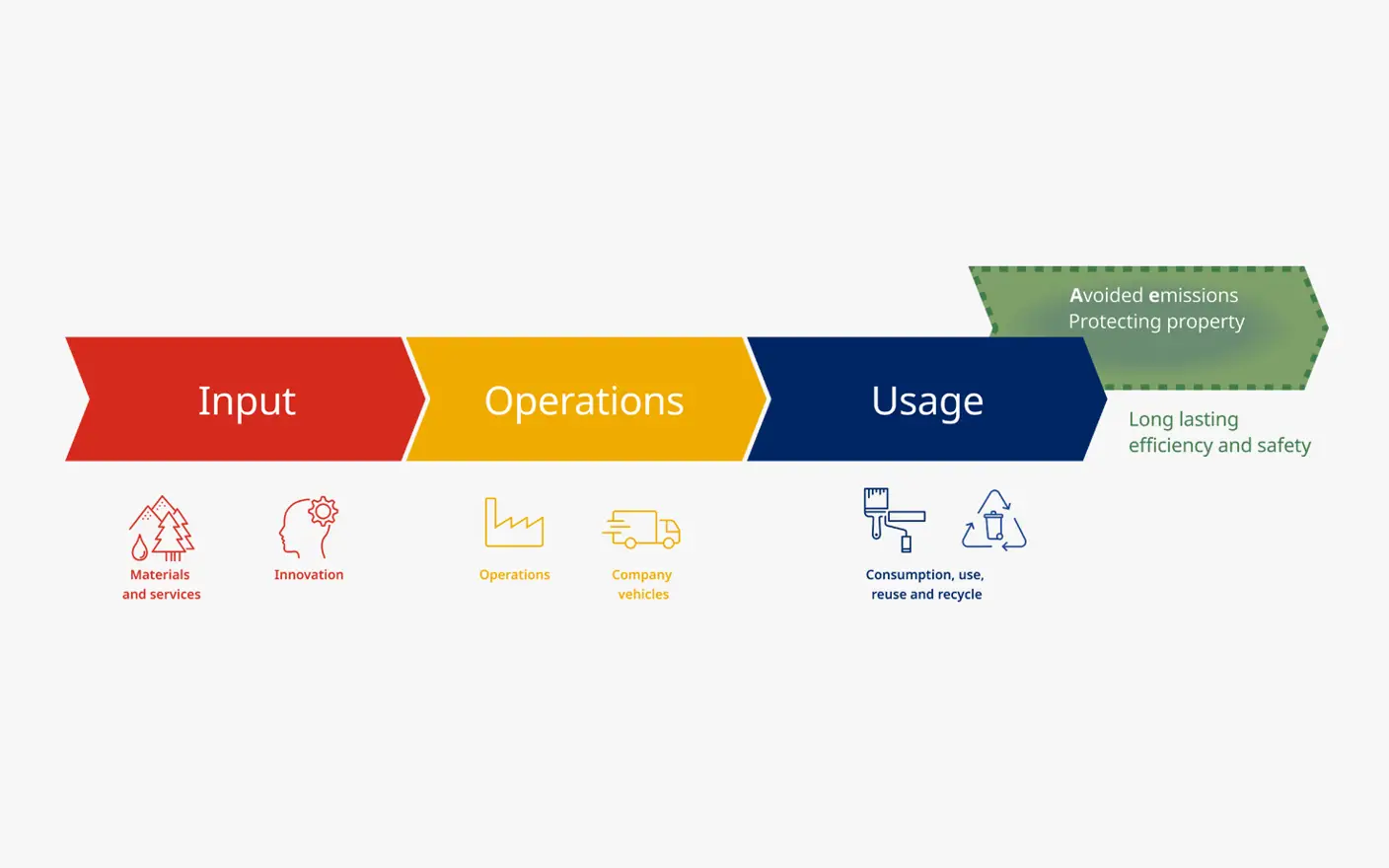

Our holistic approach minimises the environmental impact across the value chain, from sourcing raw materials and manufacturing to distribution, reuse, and recycling. We will document the environmental impact of products by using the Life Cycle Analysis as the main tool, along with other sustainability assessment approaches.

The efforts to reach our goals involve everyone at Jotun, strong partners and devoted customers. Only together can we create a truly sustainable and circular economy.

Jotun's Value Chain Model is a systematic framework that allows Jotun to understand and document the impact of products and solutions throughout the value chain and lifetime of the protected asset. The model includes the selection of raw materials and the innovation of products and solutions (Input), the impact of Jotun production activities (Operations) and how Jotun products are used, applied, and maintained (Usage). This holistic approach to sustainability enables the company to set goals and introduce activities to improve environmental performance.

Jotun conducts product Life Cycle Assessments (LCAs) that include upstream and downstream impacts to understand environmental performance. LCAs help customers comply with regulations, document their performance, and achieve their own sustainability goals. LCAs support the preparation of Environmental Product Declarations (EPDs), a standardised method of documentation that communicates transparent and comparable information about the environmental impacts of products. Jotun's EPDs are independently verified by the Norwegian Institute for Sustainability Research (Norsus). By the end of 2022, Jotun had produced more than 350 EPDs for customer groups in all segments.

Every Jotun product features unique characteristics tailored to specific customer needs. We achieve this by practising a holistic design approach. Selecting the right materials is an essential first step and a key factor in reducing our footprint.

Jotun source raw materials from suppliers that meet our social and environmental criteria. We will prioritise recycled and renewable content, with reduced content of hazardous materials and low footprint. Following Jotun’s chemical policy, our R&D teams work according to the substitution principle to reduce the use of hazardous materials.

We also focus on creating products that require fewer coats, while featuring improved application properties, reduced dry-spray and extended maintenance intervals.

The Jotun approach combines uncompromised quality and continuous sustainability enhancements, resulting in better products for people and the environment.

In Jotun's operations, our goal is to minimise environmental impacts and create safe working conditions. This also results in economic benefits, reduced risks and competitive advantages.

Jotun focuses on improving existing facilities and increased use of the environmental footprint approach as a tool for design and efficiency of new factories and facilities.

In the design of the new factories, we consider aspects which support more efficient and environmentally friendly production. This is embedded in Jotun's Engineering Standard. Examples of important initiatives we have introduced include solar panels, bulk deliveries of raw materials, and the reuse of process water and solvents.

Since 2010 we have monitored and reduced use of energy and solvents, as well as our carbon footprint, waste and VOC emissions per ton produced. Further, we set goals to eliminate inefficiencies, reuse materials and improve our environmental performance.

Energy consumption is the highest contributor to the carbon footprint from our operations. We therefore continuously work on increasing our energy efficiency and the share of renewable energy.

Other initiatives include reduction and reuse of plastics, and reprocessing of water, waste and paint. This is done through our HSEQ Management System, where all units are required to have local improvement programmes.

In most countries where we operate Jotun uses external transport suppliers and we select sustainable and low-carbon suppliers whenever possible. We focus on warehouse and vehicle capacity optimisation for efficient supply to customers, while ensuring safe and sustainable packaging and transport.

Jotun strategically reduces plastic use and contributes to closing the loop at different stages of its value chain. We explore increased use of secondary materials, and our cans are designed for ease of use, minimum leftover paint and convenient recycling.

We work closely with customers for efficient and safe preparation of surfaces, application and maintenance, and support initiatives for proper recycling of packaging and handling of waste. This supports better decisions, leading to improved durability, cost efficiency and customer satisfaction.

By documenting and sharing data on products and solutions that can contribute to avoided emissions, Jotun can support customers' sustainability goals while also reducing downstream impacts.

For example, Jotun measures how its advanced hull performance solutions reduce fuel consumption and corresponding emissions. Likewise, Jotun's long-lasting steel protection solutions prolong the lifetime of assets, thus avoiding emissions related to maintenance or the replacement of steel.

A video is being shown

An image is being displayed

A brochure is being displayed